Design Principles of Linear Piezo Actuators

Overview

There are two fundamental designs of piezoelectric actuatorsEs gibt zwei grundsätzliche Bauformen piezoelektrischer Aktuatoren:

I) Direct actuation with stacks. The most advanced type of piezo stacks is the CMA piezos (Ceramics Multilayer Actuator). These consist of numerous stacked thin layers, each less than 100 µm thick. The maximum operating voltage is 200 V or less. This type is therefore referred to as low-voltage actuation. A second, older type consists of stacked plates typically 0.5 mm thick. The operating voltage of these high-voltage actuators is typically 1000 V. Therefore, they are called high-voltage actuators.

II) Displacement-amplified piezo actuators with a special gearbox or structural effects to amplify the displacement. An example of an actuator that utilizes a structural deformation effect is the bending transducer (Smart Structures).

Bender

The displacement of bending actuators is high and can easily reach 1 mm or more. Acoustic applications of bending transducers are widespread. Telephone capsules for speakers, ultrasonic cleaners, valve actuators, and pump actuators are indispensable in our daily lives. Bending transducers utilize stress-induced deformation and generate useful displacement analogous to bimetallic strips. A bending transducer consists of multiple layers, such as a piezoelectric layer (P) and a passive carrier like a metal sheet (M). The active and passive layers are bonded together with shear rigidity. The most well-known variants are P-M, P-P, and P + -M-P. The +/- indicates the opposite phases of displacement (expansion, contraction). A thin multilayer actuator (low-profile multilayer stack actuator) can also be used as the active piezoelectric layer.

Intelligent Materials and Multifunctional Structures

Since the 1990s, an international scene has emerged dedicated to researching smart structures. The focus of research is on the development of smart or multifunctional structures. These structures are more than just load-bearing; they also integrate additional functions such as actuation, sensing, or energy harvesting. Piezoelectrics and shape memory alloys are just two examples of mechanically active materials that can be integrated into fiber-reinforced plastics. When these material components are activated, targeted stress-induced structural deformations can be triggered. Smart structures have already been successfully demonstrated for active vibration damping and aerodynamic control. Their gap-free, smooth shape makes them highly attractive for aerodynamic control elements.

Expansion of Piezo Stacks

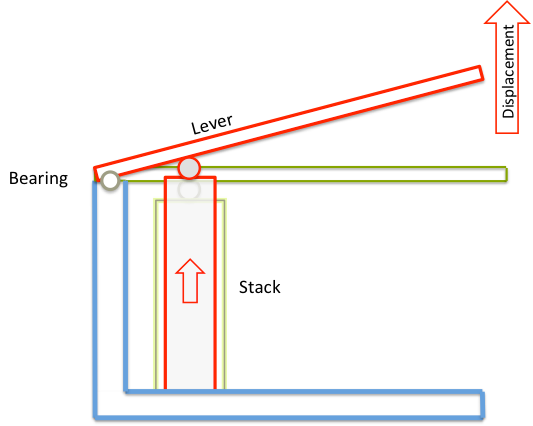

Stack actuators typically have a maximum strain of 0.1% = 1000 microstrain. Standard actuators are available with a range of displacement from 10 to 100 micrometers. This is ideal for precision positioning and other applications such as valve control and sound and vibration management. If larger displacements are required, a translation mechanism can be used

The quality and effectiveness of a translation gearbox for piezo are characterized by preserving the work capacity of the piezo stack, which serves as the drive. The work capacity is the elastic energy equal to the product of ½ free displacement and the blocking force. Deformations of the load transmission elements result in a reduction of the work capacity. Such gearboxes are custom-made, and typically, flexure joints are used to eliminate play and wear.

The next figure illustrates the principle using an optimized piezo drive for aviation. The translation mechanism transforms the expansion of the piezo stack into a pulling movement. The actuator was developed and tested for the rapid control of an aerodynamic flap in a helicopter rotor blade.