Configure Your Piezo Actuator

Piezo Stack PB

Piezo stacks in cuboid form.

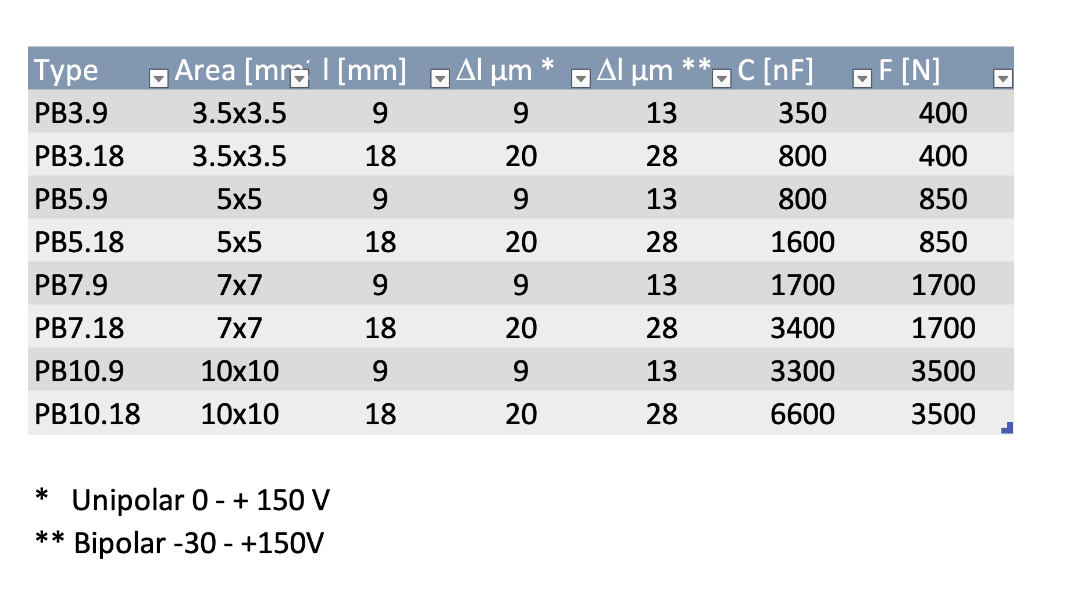

PB stacks have a square base, 3.5, 5, 7 or 10 mm wide. Length are 9 and 18 mm.

Order syntax: PB Area.Length

PB5.18: Dimensions are 5x5x18 mm

Displacement

9 mm length: 9/13 µm 0-150V (30-150V)

18 mm length: 20/28 µm 0-150V (30-150V)

Blocking Force

PB3.x F = 400 N

PB5.x: F = 850 N

PB7.x: F = 2000 N

PB10.x F = 4000 N

Other sizes, tube-shaped on request.

Piezo PA

Configured piezo stacks

PA are bonded stacks of PB elements. Length from 27 to 270 mm. Square 5, 7, and 10 mm.

Order syntax PA Area.Length

PA7.108: Dimensions are 7x7x108 mm

Displacement

Length 0 ... 150V -30 ... 150 V

36 mm 40 µm 56 µm

54 mm 60 µm 84 µm

72 mm 80 µm 110 µm

...

270 mm 300 µm 400 µm

Options

For PA and PB actuators

End pieces

- Ceramic hemispheres

- Flat plates, steel or ceramics

Strain gauges

Ceramic

hemispheres

Standard Program Piezo Stacks - PB